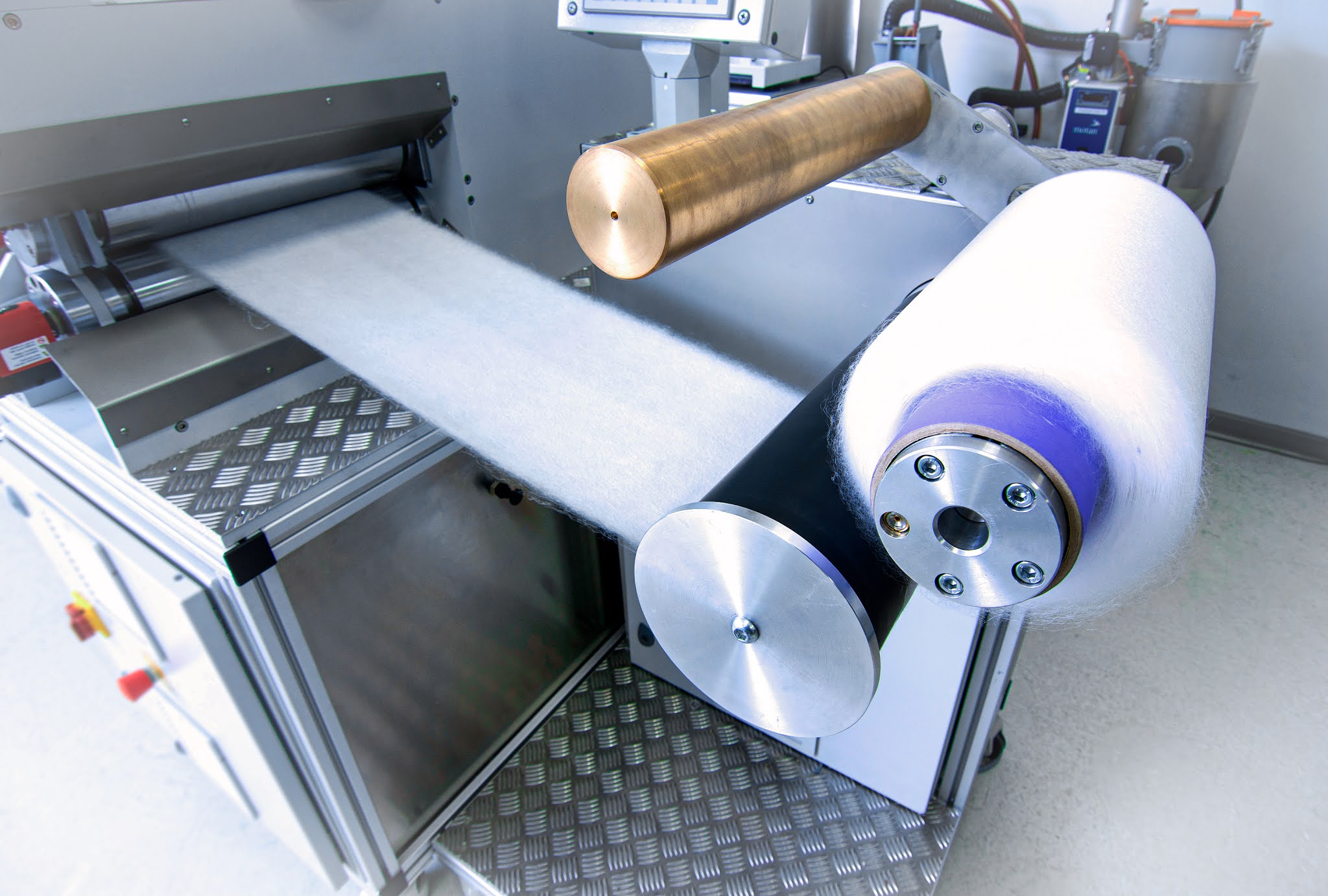

NIRI upgrades its pilot-scale capability with the latest Meltblown Technology

|

Dr Matthew Tipper, CEO at NIRI explains: “We were mindful when specifying the new equipment that we wanted to invest in the most flexible and adaptable technology available, to enable the development of a wide range of nonwoven structures – with the potential to develop unique filament and mechanical properties, further facilitating our clients’ R&D and prototyping.”

Impact of COVID-19 on meltblown demand

Dr Ross Ward, NIRI’s New Business Development Manager, comments: “In response to the COVID-19 pandemic, at NIRI we’ve been using our expertise and extensive facilities for the continued development of PPE and medical devices. This is clearly an area where our new equipment will benefit clients and ultimately, the general public. We are keenly interested in exploring the wider opportunities for meltblown nonwovens, such as developing products from bio-polymers, chemically recycled polymers and novel masterbatches with enhanced functionality. This latest development will help us facilitate the rapid development of innovative and commercially viable products for our customers”.

Applications of meltblown fabrics

Meltblown fabrics are highly versatile and can be found across a broad range of sectors and applications, ranging from use within the specialist biomedical field for the manufacturing of medical devices to use within the healthcare field for sanitary products. Meltblown fabrics are also used within air and liquid filtration, including industrial respirators and automotive cabin filters.

Accelerating the next generation of meltblown fabrics

NIRI’s scientists and engineers discuss the topic of meltblowing and how this upgrade in facilities will help accelerate the next generation of meltblown fabrics for existing and future clients.

Watch the below video to learn more

For more information on how the expansion of our facilities can further facilitate R&D and prototyping for your business, contact Dr Ross Ward at rossw@nonwovens-innovation.com

Comments

Post a Comment